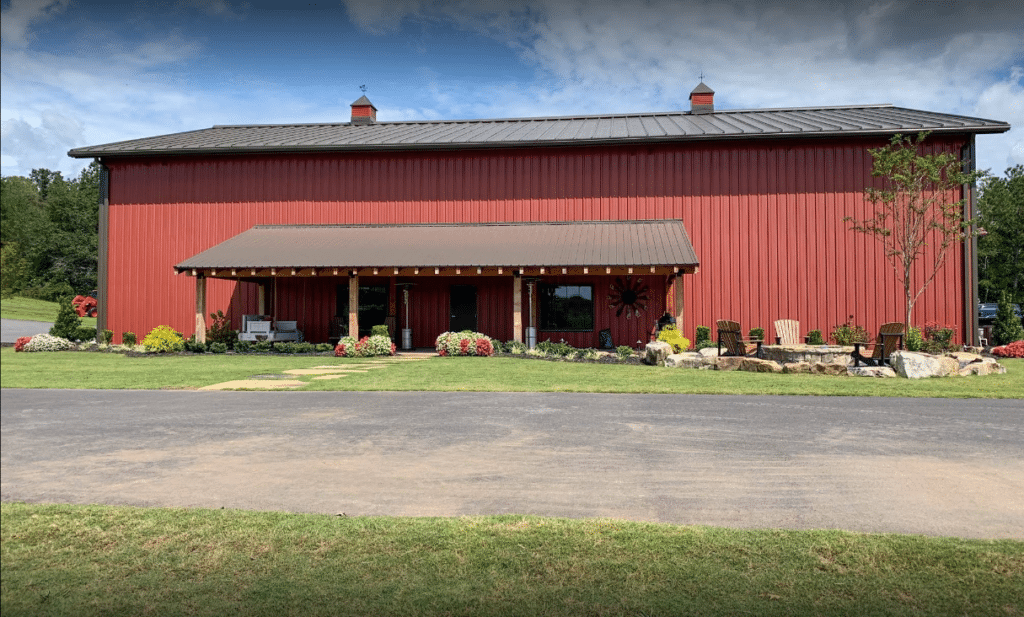

Pre-Engineered Grow House Usage

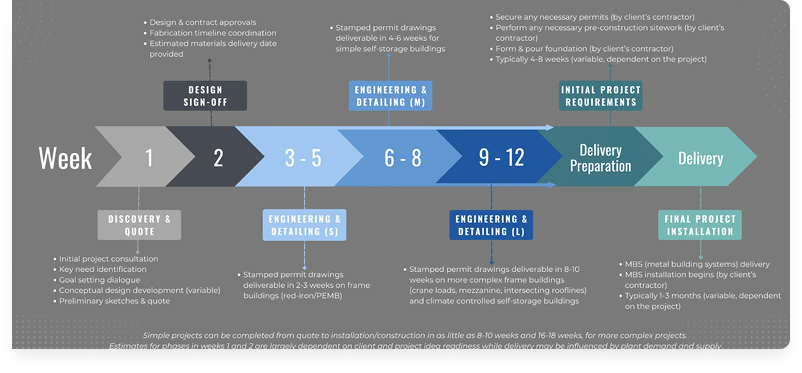

Steel’s speed, strength and precision have long powered factories, warehouses and auto centers; now the same pre‑engineered metal buildings are transforming agriculture—especially the fast‑moving medical‑cannabis and hemp sectors. Because frames are cut and drilled at the factory, entire grow houses bolt together in weeks, letting cultivators scale production quickly and get to market ahead of shifting regulations and consumer demand.