How Businesses Are Putting Steel Warehouses to Work Right Now

1 | Industrial & 3PL expansion

North‑American warehousing topped ≈ $335 billion in revenue last year and is still projected to grow 7 % annually through 2030. Third‑party logistics (3PL) firms and advanced manufacturers choose clear‑span steel warehouses for fast erection, high‑bay racking, crane rails and unobstructed forklift aisles that shave hours off every shift.

2 | E‑commerce & omni‑channel fulfillment

Online sellers live and die by speed‑to‑market. A pre‑engineered warehouse ships as a precision‑cut kit, so the shell goes up in weeks—not months—keeping inventory moving. Built‑in dock‑lines, 32‑ to 40‑ft clear heights, and optional insulated metal panels (IMPs) create an energy‑efficient, future‑proof hub for next‑day delivery.

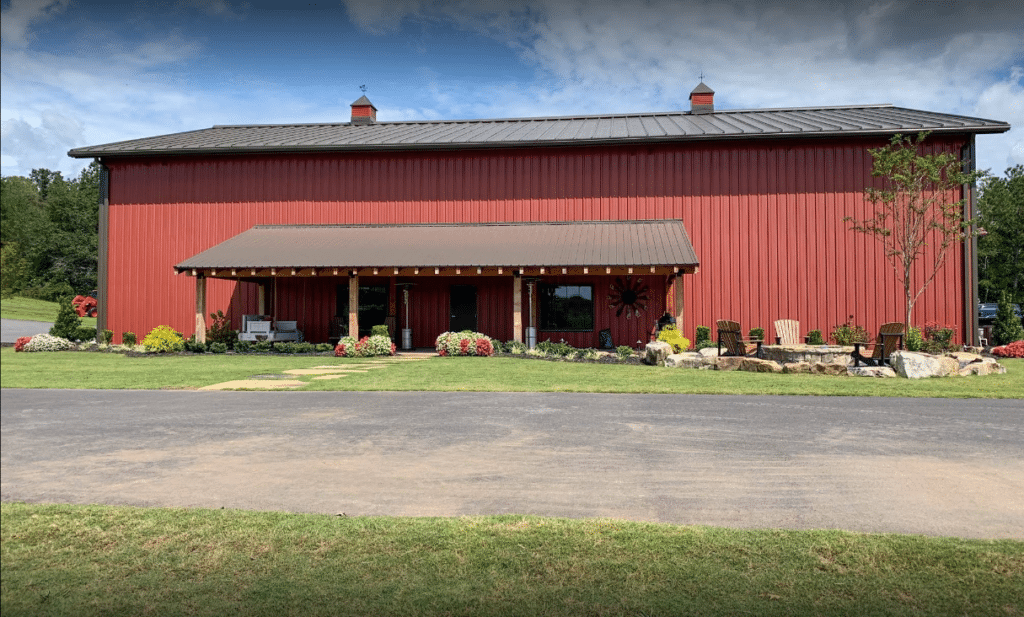

3 | Small‑ and mid‑size producers

Metal shops, modular‑home plants and food processors like the way prefab warehouses scale: start with a 60 × 120 ft shop today; bolt on 20‑ft bays tomorrow without shutting down. Standard 26‑ga PBR walls shrug off oils, steam and fertilizer dust, while galvanized secondary framing adds extra corrosion defense.

4 | Cold‑chain & specialty storage

Steel frames handle the heavy point‑loads of multi‑tier freezer racking and automated pallet shuttles. Because the structure sits outside the insulated envelope, thermal bridging is minimized—ideal for pharmaceuticals, produce or any tight‑temperature spec. Need rooftop solar? The frame is already engineered for the load.

5 | Investor‑owned “spec” space

Market analysts peg the U.S. prefab‑building segment at $43 billion in 2025, rising to $57 billion by 2030. Developers meet that demand with 32‑ to 36‑ft‑clear steel warehouses on 60 × 60 ft column grids—easy to up‑fit with mezzanines, conveyors or mini‑load AS/RS pods when a 3PL or e‑tailer signs the lease.