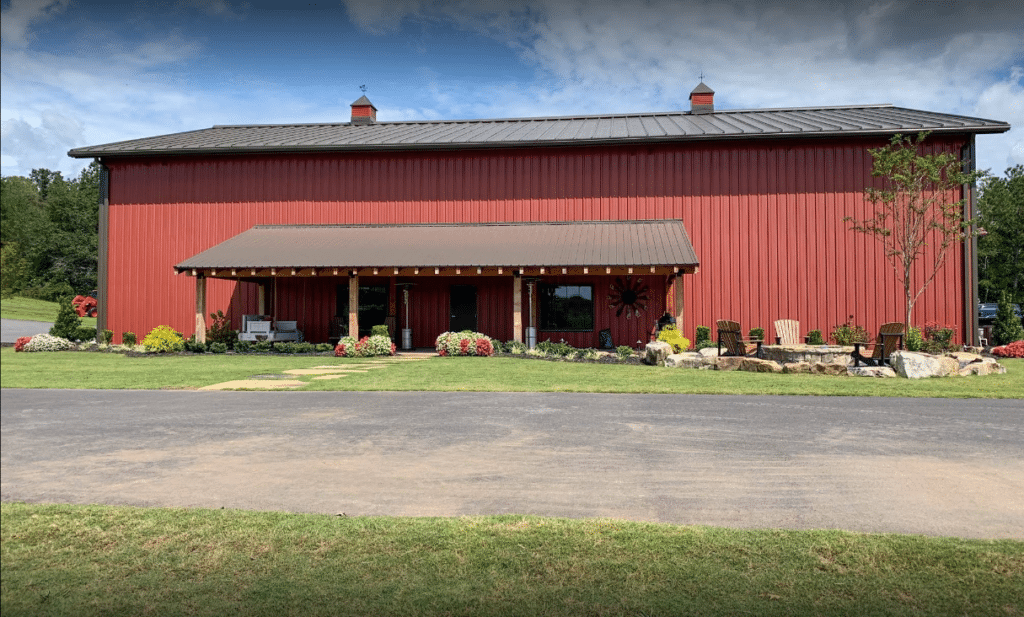

Although prefab steel commercial buildings require less maintenance intensive than other types of buildings, they still need to be looked after. Additionally, exterior veneer and decorative elements may commonly be materials other than steel, so care for those material types also need to be taken into consideration.

Here are a few tips to protect your investment and ensure the building remains functional, attractive, and holds value:

- Wash the exterior of the building every couple of months. This is primarily for corrosion prevention from contaminants and energy efficiency, but also for aesthetic and commercial appeal.

- During the winter, check the roof after every snow fall. Although your roof is designed to bear heavy loads, it’s best to remove snow if it’s over four inches high.

- Make sure you check gutters and drains periodically and clean out bird’s nests, leaves and so on. Why put gutters on a steel building? To make sure that rain water and snow melt run off away from your sidewalks and in particular your doors. Not only will this protect the foundation of your building, but your customers will appreciate it as well.

Regular maintenance of your prefab steel commercial building ensures its longevity, functionality, and aesthetic appeal. By following these simple tips, you can protect your investment, maintain its value, and provide a safe and welcoming environment for your employees and/or customers.