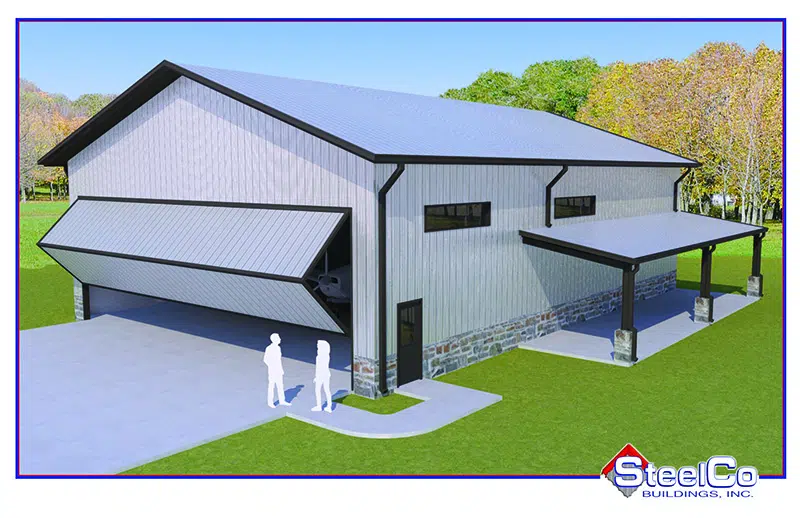

Customized Hangar Designs

Door system

We also offer all the door systems possible for hangars, from bi-fold doors (which raise upward) to bottom rolling doors (which slide open to either side) to allow easy ingress and egress of planes; to walk through doors along the side to allow for easy ingress and egress of people.

Windows

Windows and skylights let in available light and can help improve the usability of the hangar.

Living/office quarters

If you’d like a hangar designed with an upstairs living quarters, or office, we can do that. Simply contact us and let us know your needs.

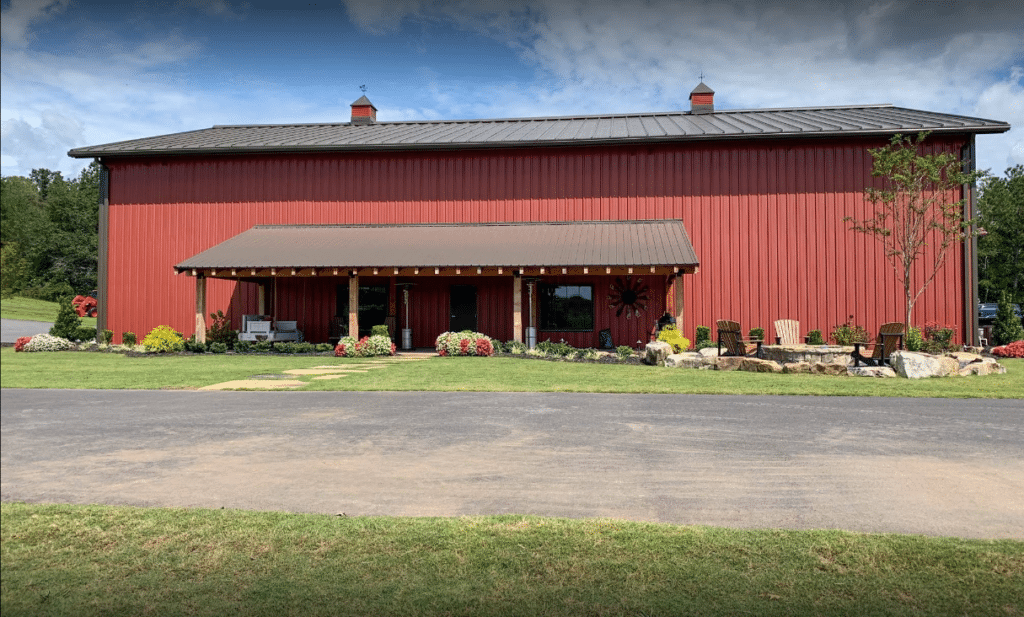

Sturdiness

The whole point of a hangar is to protect your aircraft from the elements. Our hangars are designed to withstand windstorms as well as heavy ice or snow on the roof.

Your local area will have its own building codes. Our pre-engineered aircraft hangars meet or exceed all business codes. We have the experience and we know what’s needed.

Insulation

Depending on your location, you may or may not want your steel aircraft hangar to be insulated. If you wish your hangar to be insulation-ready, we can comply.

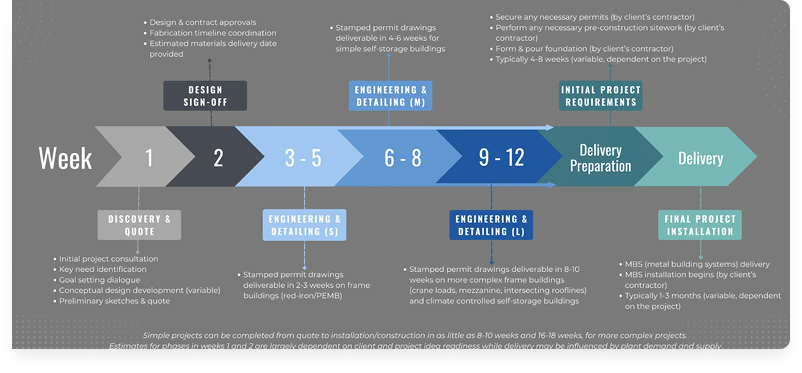

Depending on the complexity of your hangar design, it can range anywhere from 8 to 12 weeks to prefab every piece of equipment to our exacting specifications – and yours. Once everything is ready, it’s drop-shipped right to you. We will dropship your pre-engineered aircraft hangar(s) anywhere in the continental United States.